services

The eco-friendly Ecochrome process is completely free of environmentally and health-hazardous chromium 6. Customers get a glossy chrome or aluminum look on their products. In our PVD facility, the articles are put in a vacuum-tight chamber where a very thin layer of pure chrome or aluminum is applied using sputtering technology. The metal evaporates in the vacuum to a gas cloud which then condenses on the articles. No environmentally hazardous baths are used. The metal can be applied on many different types of materials. If the material can get adhesion in a wetpainting process, then the surface is also good for vacuum metallization.

painting

DECORATION

INJECT MOULDING

Installation

Water Transfer Printing

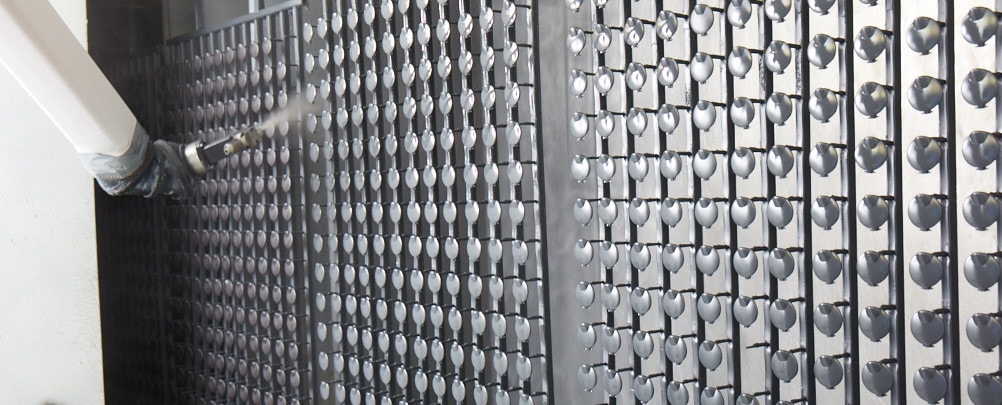

Make your product unique by adding Water Transfer Printing

First we put a film with a decorative pattern on the surface of a water tub and then we spray an activator on the film so that it dissolves. After that the product is dipped in the patters and then it is washed, dried and coated with a clear – or matcoat depending in the customers preference.

There are numerous different patterns to choose between, like marble, wood, stone, carbon fibre, water etc. Water Transfer Printing can be applied on many different materials such as plastic, metal, glass and wood.